Manufacturing's Digital Workforce: Beyond Automation to Intelligent Production

The manufacturing industry is often the source of innovation. From the first assembly lines to today's robotic arms and connected machines, the sector has continuously pushed the boundaries of what automation can achieve. The next evolution in manufacturing isn't simply about adding more robots or connecting more sensors though. It's about creating intelligent production environments where AI agents work alongside humans and machines, forming a digital workforce capable of perceiving, reasoning, and acting across entire manufacturing ecosystems.

The Limits of Traditional Automation

For decades, automation has been the manufacturing industry's primary tool for improving efficiency. Robotic systems perform repetitive tasks with precision. Programmable logic controllers manage production sequences. Automated quality inspection systems flag obvious defects. These technologies have delivered enormous value, but they share a common limitation: they execute predefined tasks within rigid parameters.

Traditional automation excels at doing the same thing repeatedly, but it struggles with variability. When conditions change, when unexpected problems arise, or when optimization opportunities emerge, these systems require human intervention. They can't learn from experience, adapt to new patterns, or coordinate across different domains without explicit programming.

Intelligent Collaboration

Agentic AI is a departure from task-specific automation toward systems that can perceive their environment, reason about what they observe, and take meaningful actions across interconnected platforms. Unlike traditional automation, AI agents don't just execute; they understand, learn, and improve.

Think of the digital workforce as a mesh of specialized AI agents, each focused on specific domains but capable of communicating and coordinating with one another. These agents integrate across ERP systems, Manufacturing Execution Systems (MES), Supply Chain Management (SCM) platforms, and IoT sensor networks. The result is a production environment that doesn't just run according to plan but actively thinks about how to improve.

This creates something genuinely new: factories that learn from every production run, optimize themselves in real time, and make intelligent decisions without waiting for human approval in routine situations.

Intelligent Supply Chain Agents: Orchestrating the Flow

Supply chains have always been complex, but today's global manufacturing networks face increasing volatility. Lead times fluctuate, suppliers face disruptions, transportation costs vary, and demand patterns shift rapidly. Managing this complexity requires more than static planning models.

Enter intelligent supply chain agents that continuously monitor and adjust procurement, inventory levels, and logistics based on real-time data and predictive models. These agents don't wait for problems to cascade through the system; they anticipate and respond.

Consider a realistic scenario: A materials planning agent detects that a key supplier is experiencing delays based on shipping data and supplier communications. Rather than simply flagging this for human review, the agent immediately coordinates with a logistics agent to identify alternative routing options. The logistics agent reroutes shipments from warehouses with available inventory and automatically updates ERP forecasts to reflect the new timeline. A procurement agent simultaneously evaluates backup suppliers and initiates communication if the delay exceeds acceptable thresholds.

This kind of dynamic orchestration reduces lead times, minimizes costly stockouts, and builds resilience against the inevitable disruptions that affect modern supply chains. The key enabler is an integration layer, often using protocols like Model Context Protocol (MCP) or Agent-to-Agent (A2A) communication standards, that allows agents to share data and coordinate actions across organizational boundaries.

Quality Control Agents

Quality is critical in manufacturing, but traditional approaches rely heavily on sampling and post-production inspection. By the time a defect is detected, dozens or hundreds of flawed units may have already been produced.

Quality control agents transform this reactive model into something predictive and continuous. Using AI vision systems and sensor data analysis, these agents monitor production in real time, examining visual characteristics, dimensional accuracy, and process parameters for every unit on the line.

When an anomaly appears, the response is immediate and intelligent. The agent doesn't just flag a problem; it initiates corrective workflows. It might adjust machine parameters to bring the process back within tolerance, notify maintenance teams if it detects equipment drift, or even pause production if the issue is serious enough to warrant immediate human attention.

What makes this truly powerful is the learning loop. Each detection, each correction, and each outcome feeds back into the agent's model. The system becomes more accurate over time, learning to distinguish between minor variations and genuine defects, understanding the subtle patterns that precede quality issues, and optimizing its interventions for maximum effectiveness.

The outcome is a shift from reactive inspection to predictive quality. Waste decreases, compliance improves, and manufacturers can deliver higher quality with greater consistency.

Predictive Maintenance Agents

Equipment failures are one of manufacturing's most persistent challenges. Traditional maintenance approaches are either calendar-based (replacing parts on a fixed schedule regardless of condition) or reactive (waiting for something to break). Both are inefficient and costly.

Predictive maintenance agents change this calculus entirely. By continuously analyzing sensor streams (vibration patterns, temperature fluctuations, acoustic signatures, power consumption), these agents learn the normal operating profile of each machine and detect subtle deviations that signal impending failure.

But the real power emerges through agent collaboration. When a maintenance agent forecasts that a motor is likely to fail within the next two weeks, it doesn't just generate an alert. It coordinates with production scheduling agents to identify the optimal maintenance window that minimizes disruption to current orders. It communicates with supply chain agents to ensure replacement parts are available when needed. It updates capacity planning models so production planners can adjust schedules accordingly.

The results are compelling: higher equipment uptime, lower maintenance costs, and optimized asset utilization. Manufacturers move from fighting fires to managing assets strategically.

Human-Agent Collaboration

A common fear about AI in manufacturing is that it will replace human workers. The reality of agentic AI is far more nuanced and ultimately more powerful. These systems augment human capabilities rather than replacing them.

Humans bring creativity, judgment, strategic thinking, and the ability to handle truly novel situations. AI agents bring tireless monitoring, rapid data processing, pattern recognition at scale, and the ability to coordinate complex workflows across systems. Together, they form a partnership more capable than either alone.

Modern agent interfaces make this collaboration natural. Technicians and production planners can "converse" with factory AI agents using natural language. A maintenance supervisor might ask, "Why did you recommend postponing the line 3 service?" and receive a clear explanation of the reasoning, including the data points that influenced the decision and the trade-offs considered.

This transparency builds trust. When agents explain their reasoning, highlight anomalies they've detected, and recommend actions with clear justification, humans can make better decisions about when to follow agent recommendations and when to exercise their own judgment.

The factory floor becomes a collaborative environment where digital teammates handle routine monitoring and optimization while humans focus on improvement, innovation, and the complex problem-solving that still requires human insight.

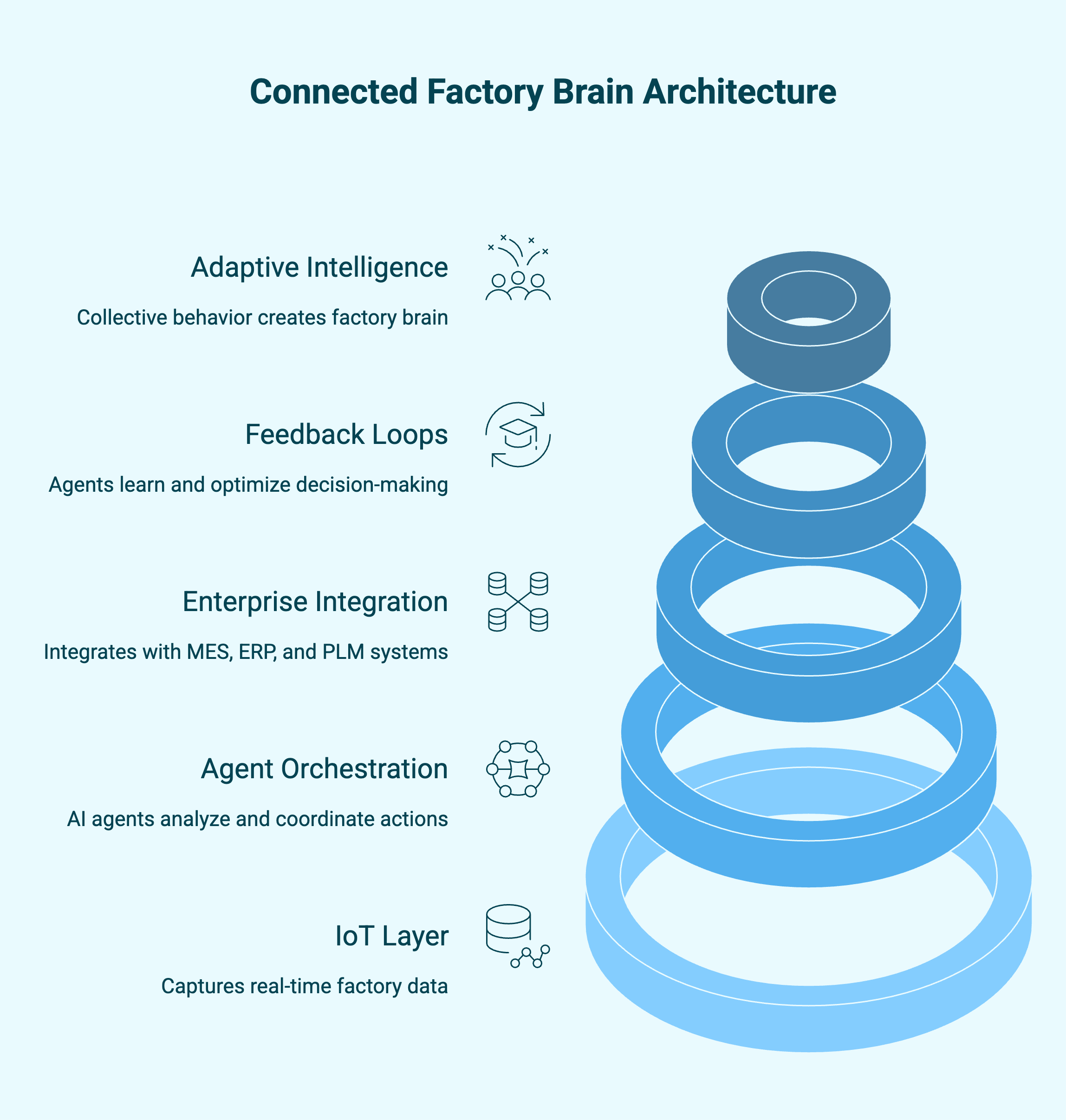

Architecture of the Connected Factory Brain

Creating an effective digital workforce requires thoughtful system architecture. The foundation is an IoT layer that captures real-time data from sensors, machines, and production processes across the factory floor. This data flows into an agent orchestration layer where specialized AI agents analyze patterns, make decisions, and coordinate actions.

These agents integrate deeply with existing enterprise systems: MES for production execution, ERP for resource planning, and Product Lifecycle Management (PLM) for design and engineering data. The architecture includes robust feedback loops so agents can learn from outcomes and continuously optimize their decision-making.

What emerges from this connected infrastructure is something like a factory brain. No single agent has complete knowledge or control, but the collective behavior of multiple agents acting across traditional organizational silos creates an adaptive intelligence. The whole becomes greater than the sum of its parts.

Why Digital Workforces Matter

The benefits of moving to a digital workforce model extend across multiple dimensions:

Operational agility increases dramatically. When demand patterns shift or product specifications change, the production environment can reconfigure itself dynamically rather than requiring extensive reprogramming and retooling.

Cost efficiency improves through optimized processes, minimal downtime, and better resource utilization. Agents continuously identify small improvements that compound over time.

Sustainability advances as agents minimize waste and optimize energy consumption. By understanding the relationship between process parameters and resource usage, agents can find efficiency gains that reduce environmental impact while cutting costs.

Resilience strengthens as the system develops the ability to adapt rapidly to supply shocks, equipment issues, or market shifts. The digital workforce doesn't panic or get overwhelmed; it processes new information and adjusts accordingly.

Charting Your Implementation Path

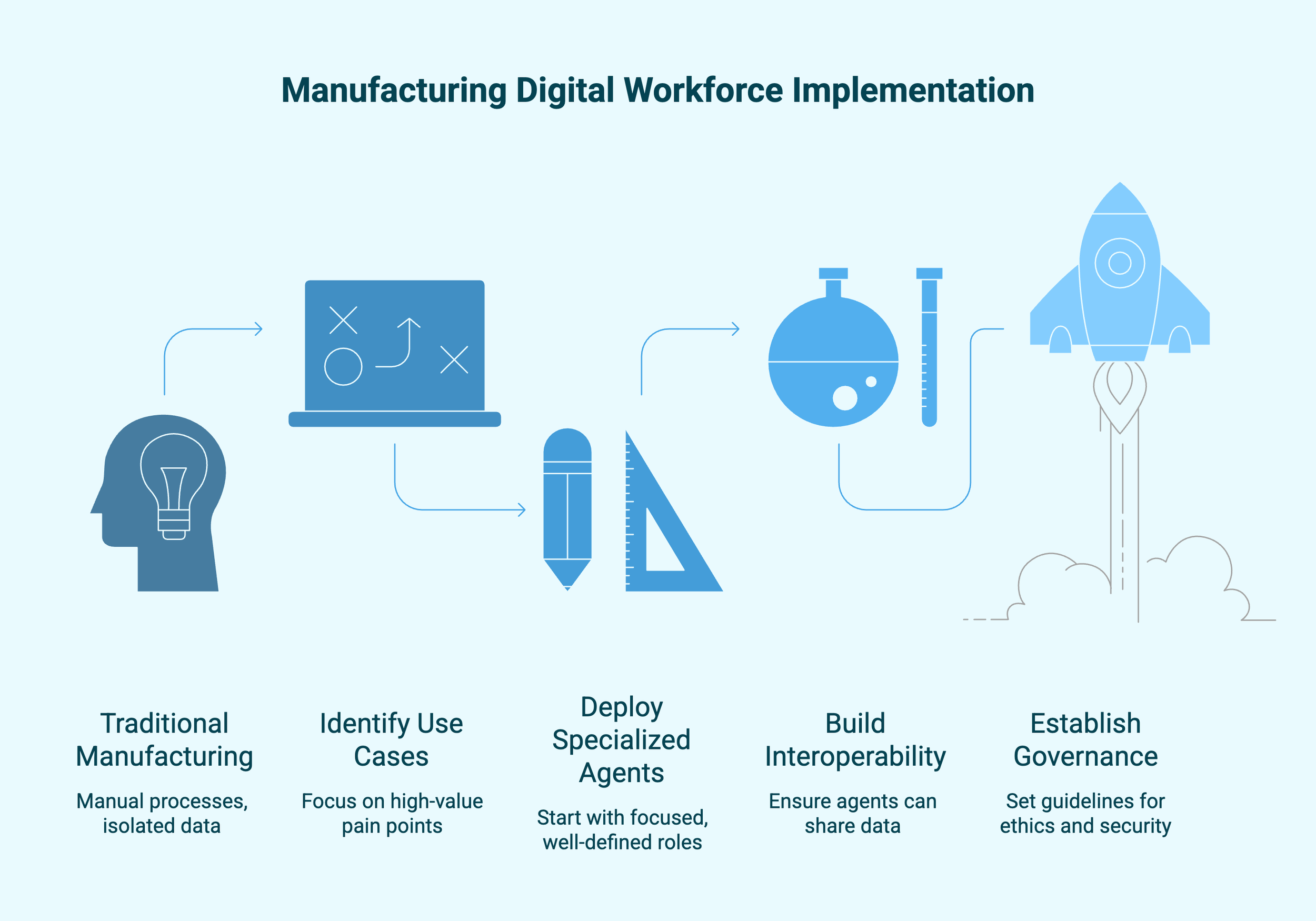

Moving to a digital workforce model doesn't happen overnight, but manufacturers can chart a clear path forward:

Start with high-value use cases. Identify specific pain points where intelligent agents can deliver measurable impact: quality control systems that catch defects earlier, maintenance agents that prevent costly breakdowns, or planning agents that optimize inventory levels.

Deploy specialized agents with clear scopes. Begin with focused agents that have well-defined responsibilities and key performance indicators. This allows you to build expertise, demonstrate value, and learn what works before scaling.

Build interoperability from the start. Use standard APIs and agent communication protocols so your agents can share data and coordinate actions. Avoid creating isolated islands of intelligence.

Establish governance frameworks. Set clear guidelines for ethics, data integrity, and security. Define when agents can act autonomously and when human approval is required. Create accountability structures.

Scale toward ecosystem coordination. As individual agents prove their value, expand toward a coordinated multi-agent production ecosystem where agents across different domains work together seamlessly.

The Adaptive Factory Future

The manufacturing facilities taking shape today look very different from the automated plants of the past. These adaptive factories don't just make things; they think about how to make things better. They learn from experience, coordinate across complex networks, and collaborate with human workers in ways that enhance everyone's capabilities.

Agentic AI is the fusion of automation and cognition. It takes the efficiency and precision of automated systems and adds the adaptability and intelligence that only learning systems can provide.

The opportunity isn't about replacing labor; it's about unlocking a new tier of productivity and innovation. It's about building production environments that can thrive in an era of rapid change, customization, and complexity. It's about creating factories that are not just smart, but genuinely intelligent.

The question for manufacturing leaders isn't whether to pursue this transformation, but how quickly they can move to capture its benefits. The digital workforce is already here. The factories that embrace it will define the future of manufacturing.